ACIS Science Instrument

Software User’s Guide

36-54003 Rev. B

February 14, 2022

DR SDM05

Contract # NAS8-37716

Submitted to:

George C. Marshall Space Flight Center

National Aeronautics and Space Administration

Marshall Space Flight Center, AL 35812

Submitted By:

Massachusetts Institute of Technology

Center for Space Research

77 Massachusetts Avenue

Cambridge, MA 02139

| Approvals: | |

| | |

| Dr. Peter Ford | Dr. Mark Bautz |

| Software Project Manager | Project Manager |

| Massachusetts Institute of Technology | Massachusetts Institute of Technology |

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

KAVLI INSTITUTE FOR ASTROPHYSICS & SPACE RESEARCH

CAMBRIDGE, MASSACHUSETTS 02139

REVISION LOG

ACIS Science Instrument Software User’s Guide

DOC. NO. 36–54003 Rev. B

|

|

|

|

|

|

| | Date | ECO | Page(s) | | |

| | (mm/dd/yy) | No. | Affected | |

|

|

|

|

|

|

|

| 01 | 5/30/1997 | 36-923 | All | Initial

Skeleton | – |

|

|

|

|

|

|

| A | 7/21/1999 | 36-957 | All | Initial

Version,

released

with

TBDs

at

launch

time | RFG |

|

|

|

|

|

|

| B- | 4/28/2020 | N/A | All | Revised

Version,

incorporating

20

years

of

on-orbit

experience,

reviewed

by

the

ACIS

instrument

team | – |

|

|

|

|

|

|

| B | February 14, 2022 | 36-1055 | All | Baseline

Release | – |

|

|

|

|

|

|

| |

Table of Contents

List of Figures

List of Tables

Section 1

Introduction

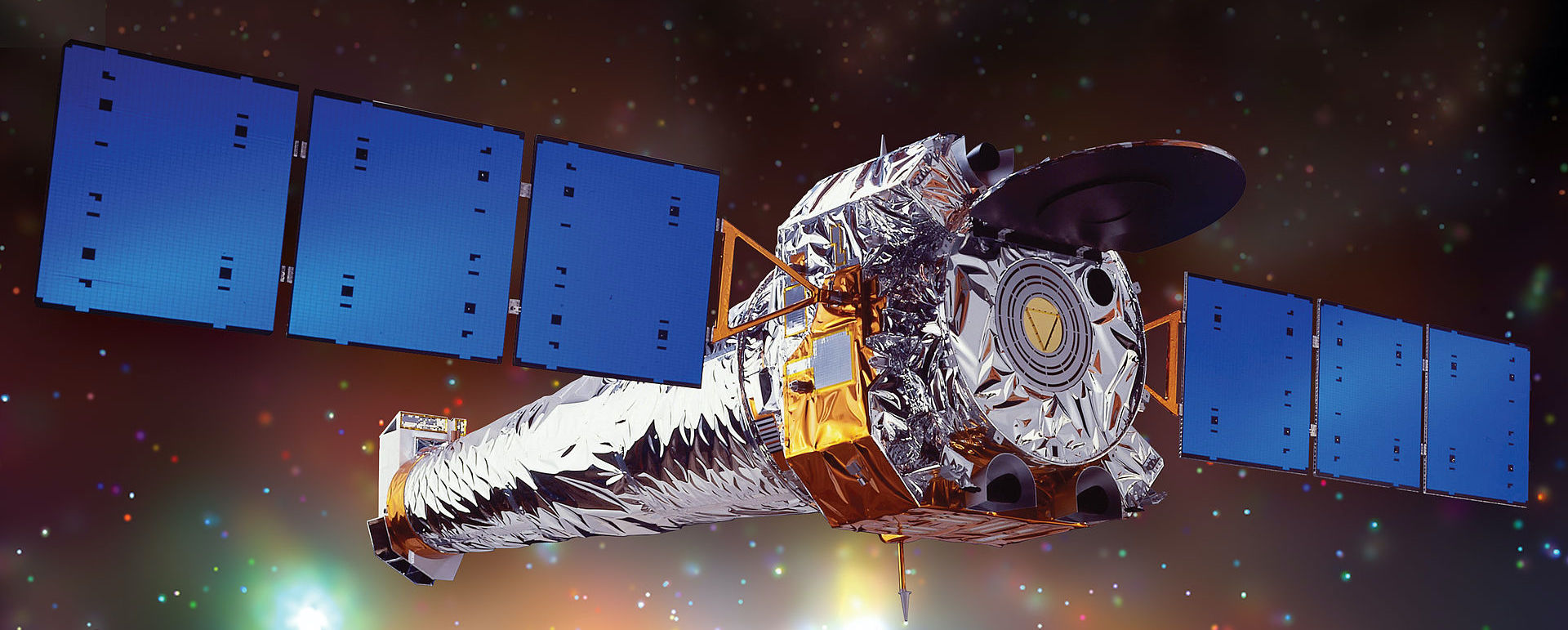

The AXAF-I CCD Imaging Spectrometer (ACIS) Science Instrument Software (SIS) was developed by the

Massachusetts Institute of Technology, Center for Space Research (MIT-CSR) as part of the ACIS Digital Processor

Assembly (DPA). The DPA resides on-board the Advanced X-ray Astrophysics Facility - Imaging (AXAF-I). The

DPA Science Instrument Software is responsible for acquiring and processing image data from the ACIS CCD

Imaging Spectrometer and transferring the processed data to the AXAF-I Command and Telemetry Unit (CTU),

which is then responsible for sending the information to the ground. On orbit, ACIS is operated by its Science

Operations Team (SOT).

1.1 Purpose

The ACIS Science Instrument Software User’s Guide describes the operation of the key functions of the instrument

software.

1.2 Scope

This document applies to the detailed design of the ACIS DPA Science Instrument Software. It does not provide

information for the Ground Support Software (GSS), which is maintained separately as part of the Electronic

Ground Support Equipment (EGSE).

This document supplies information applicable to SDM05 from the original contract, and to DM29 from

MM8075.1.

By mutual agreement, MSFC Software Management and Development Requirements Manual MM8075.1, which

supersedes MA-001-006-2H, forms the basis for this document.

1.3 References

This specification relies on a set of existing documentation. The following table lists these documents.

Table 1.1: Reference Documents

|

|

|

|

| Part Number | Rev | Date | Title

|

|

|

|

|

| MSFC MM 8075.1 | | 01/22/1991 | MSFC Software Management and Development

Requirements Manual |

|

|

|

|

| MIT-CSR 36-01103 | I | 05/16/1997 | ACIS Science Instrument Software

Requirements Specification |

|

|

|

|

| MIT-CSR 36-01502 | C | | ACIS Hardware Specification and System

Description |

|

|

|

|

| MIT-CSR 36-01410 | | 01/15/1997 | ACIS Instrument Protocol and Command List |

|

|

|

|

| MIT-CSR 36-53204.0204 | N | 03/15/2001 | ACIS IP&CL Software Structure Definitions |

|

|

|

|

| MIT-CSR 36-02205 | C | 11/14/1996 | DPA/DEA Interface Control Document |

|

|

|

|

| MIT-CSR 36-55001 | 3.1 | 06/20/1997 | ACIS Test Tools |

|

|

|

|

| MIT-CSR 36-54002.08 | 1.5 | | ACIS Flight Software |

|

|

|

|

| MIT-CSR 36-56102 | 1.1 | 07/29/1996 | Huffman Coding of ACIS Pixel Data |

|

|

|

|

| MIT-CSR 36-56101 | 2.1 | 07/19/1995 | CCD Bias Level Determination Algorithms |

|

|

|

|

| ACIS-PSU-SOP-01 | 2.65 | 11/20/1997 | ACIS Science Instrument Operations Handbook |

|

|

|

|

| NU910701 | | 1991 | Nucleus RTX Reference Manual from

Accelerated Technology, Inc. |

|

|

|

|

| NU910702 | | 1991 | Nucleus RTX Internals Manual from Accelerated

Technology, Inc. |

|

|

|

|

| MIPS RISC Architecture | | 1989 | Kane, Prentice Hall, NJ |

|

|

|

|

| MIPS Programmers

Handbook | | 1994 | Farquhar & Bunce, Morgan Kauffman

publishers, San Francisco, CA |

|

|

|

|

| Error Correction Coding | | 2005 | Moon, T.K., Wiley & Sons. |

|

|

|

|

| |

Several topics related to ACIS Flight Software are covered in a series of online reports, available from

“http://acisweb.mit.edu/pub/File.pdf”, where “File” is the third column of Table 1.2.

Table 1.2: ACIS Flight Software Reports

Section 2

Overview

2.1 Instrument Hardware Overview

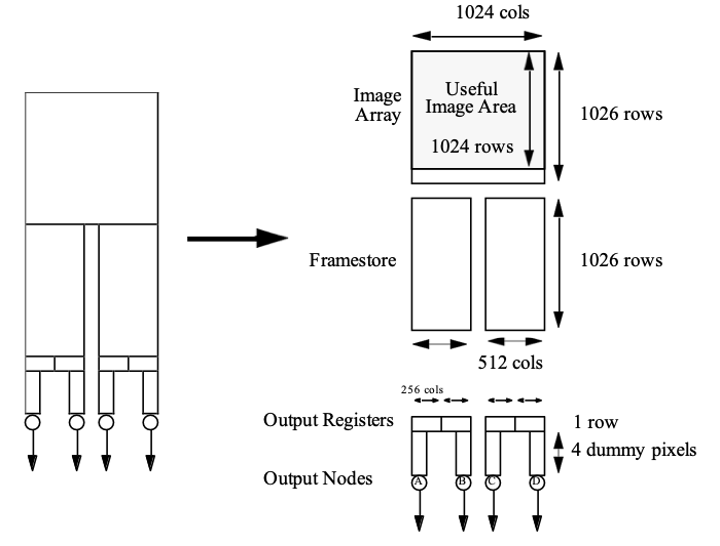

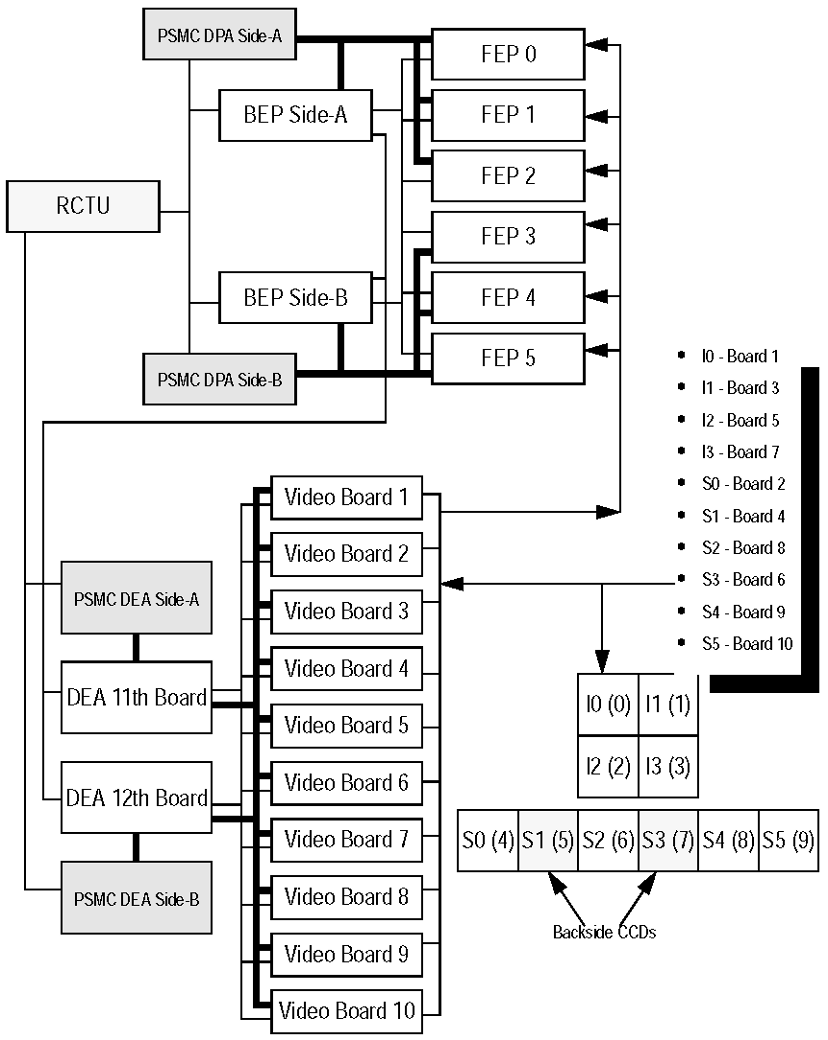

Figure 2.1 illustrates the overall hardware architecture of ACIS.

-

RCTU - Remote Command and Telemetry Unit

-

This provides the command and telemetry interface between ACIS and the spacecraft.

-

PSMC - Power Supply and Mechanism Controller

-

This provides power to the ACIS Digital Processor Assembly (DPA), which contains the Back End

Processors and Front End Processors, and to the Detector Electronics Assembly (DEA), which contains

the CCD Video Controller Boards and two interface boards. It is also responsible for controlling

the ACIS door, vent valves, etc. (not shown). All of the PSMC functions are controlled by discrete

commands received from the spacecraft; no instrument software is involved.

-

BEP - Back End Processor

-

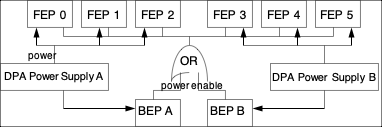

ACIS has two redundant Back End Processors, responsible for the overall control of the instrument,

including command and data handling. Although both BEPs are usually powered at the same time, only

one BEP is active at a time.

Each BEP is powered by a separate side of the PSMC DPA Power Supply.

-

FEP - Front End Processor

-

ACIS has 6 Front End Processors that are responsible for acquiring digitized image data from the

CCD Video Controllers, and for detecting candidate X-ray events from these images. For a normal

science observation, data from each CCD used for the observation is processed by any one of the 6

FEPs (NOTE: it is possible, however, to have more than one FEP process data from the same CCD).

FEPs 0, 1, and 2 are powered by A-side of the PSMC DPA Power Supply, and FEPs 3, 4, and 5 are

powered by the B-side of the supply. In order to process data from 6 CCDs simultaneously, both sides

of the PSMC DPA Power Supply must be on.

-

11th Board

-

This is the primary interface board for the Detector Electronics Assembly. It contains power switching

logic for the DEA Video Boards, a Focal Plane temperature controller, and some housekeeping logic.

These components are powered by the A-side of the PSMC DEA Power Supply. This board also contains

a set of relays used to switch power on the video boards to the current PSMC DEA Supply. Unlike the

DPA only one side of the PSMC DEA Power Supply may be on at a time.

-

12th Board

-

This board is a backup interface board for the DEA. It is identical to the 11th board except that it does

not have the power-switching relays, nor does it have the housekeeping logic. This board is powered

by the B-side of the PSMC DEA Power Supply.

-

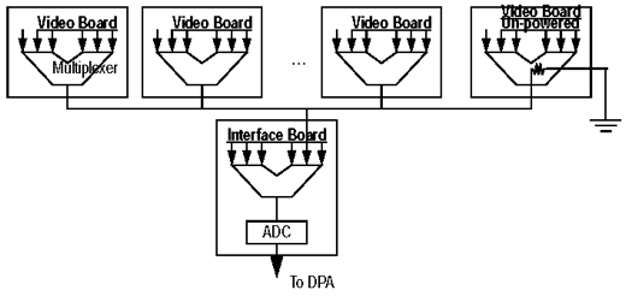

Video Boards

-

ACIS has 10 DEA Video Boards. Each board is hard-wired to a particular CCD (see diagram for the

mapping). Each video board contains a sequencer (loaded by the BEP) that is used to transfer charge

within the CCDs. Each also contains digitization circuits to convert the analog CCD data into a digital

form, which is then fed to the FEPs.

The ACIS Mongoose processors are all configured by hardware to use little-endian” byte ordering. For example, the

32-bit value 0x12345678 (decimal 305419896) is stored as bytes in RAM as follows:

| Virtual Address | Byte Value

|

|

|

| 0 | 0x78 |

| 1 | 0x56 |

| 2 | 0x34 |

| 3 | 0x12 |

By convention, bits within a word are numbered with the least-significant bit as bit number 0. This is consistent

with the usage in the “MIPS Programmers Handbook” (see Table 1.1.) Unless otherwise specified, all signed values

use two’s complement representation.

2.2 Instrument Software Overview

The ACIS Instrument Software runs on two types of processors within the system: the Back End Processor (BEP)

and the set of Front End Processors (FEP). The BEP loads its software either from EEPROM or from the uplink

command channel. Once up and running, the active BEP can enable power to the FEPs and to video boards within

the Detector Electronics Assembly (DEA), and load software into the FEPs via shared memory, and into the video

processors using serial digital interfaces.

The BEPs run a single-processor preemptive, multi-tasking kernel that allows the BEP to be performing more than

one task at a time. For example, it can process science data, while acquiring DEA housekeeping data, while

performing a memory dump (BTW: This is a very useful feature when trying to diagnose certain classes of

problems). The telemetry produced by the BEP is organized into data packets, which appear in the “Software

Serial Data” portion of the telemetry stream (IP&CL mnemonic 1TSERXT). Each packet is preceded by

a 32-bit synchronization pattern, and contains a length field indicating the number of words in the

packet. This allows telemetry produced by the several tasks running on the BEP to be merged into the

telemetry stream (for example, memory dump telemetry packets may be mixed in with science event data

packets).

Table 2.1 lists the BEP’s tasks, grouped according to their priority (highest priority, 51, is first, and lowest priority

listed, 55, is last. Tasks with the lowest priority number have the highest run-time priority). In contrast, each FEP

runs a single main thread, with a single interrupt handler to count the arrival of images produced by the DEA. The

FEPs are only commanded by the software that runs on the active BEP. This single thread performs the

high-performance portion of the science data processing, and polls its shared memory interface for requests from the

BEP.

The shared memory interface was designed to permit the BEP to copy entire FEP bias maps into telemetry packets

while simultaneously processing X-ray events, but this behavior caused FEP firmware to lock-up at times of high

event rates. Software patches (buscrash, buscrash2) to prevent this have since been installed in the BEP, but it is

still possible to command the BEP to dump the contents of a FEP processor’s memory to telemetry, e.g., for

diagnostic purposes (see Section 3.6.1.3), provided the FEPs are not processing CCD frames at the

time.

Table 2.1: BEP Tasks

|

|

|

|

| Task Name | Prio | Command/Telemetry | Role

|

|

|

|

|

| TaskMonitor | 51 | Not

commandable. | Perform

aliveness

tests

of

the

other

tasks.

Allows

the

watchdog

timer

to

reset

the

BEP

if

a

task

fails

to

respond

to

a

query

within

8

minutes. |

|

|

|

|

| CmdManager | 52 | All

software

commands

executed

or

routed

by

this

task. | Interpret

and

dispatch

uplinked

commands. |

|

|

|

|

| SystemConfiguration | 53 | Radiation

Flag

and

Change

System

Configuration. | Respond

to

changes

in

configuration

table

and

monitor

the

radiation

flag. |

|

|

|

|

| SwHousekeeper | 53 | Not

commandable.

Produce

software

housekeeping

packets. | Collect

and

periodically

report

software

statistics.

Update

software

bi-levels

to

reflect

instrument’s

operating

state. |

|

|

|

|

| DeaHousekeeper | 53 | Start/Stop

DEA

Housekeeping. | Periodically

collect

and

report

DEA

housekeeping

values. |

|

|

|

|

| MemoryServer | 54 | Dump

commands,

Read,

Write

BEP/FEP/PRAM/

SRAM

commands,

Execute

BEP/FEP

commands. | Handle

read

(including

dump),

write,

and

execute

memory

commands. |

|

|

|

|

| BiasThief | 55 | Affected

by

start/stop

science/bias-only

commands,

via

ScienceManager. | Trickle

the

contents

of

the

computed

CCD

bias

maps

to

telemetry. |

|

|

|

|

| ScienceManager | 55 | Execute

start/stop

science

runs

and

bias-only

science

runs. | Perform

science

run,

including

hardware

setup,

parameter

dumps,

bias

computation

and

data

processing. |

|

|

|

|

| |

2.3 Commands and Telemetry

ACIS is commanded via its Remote Command and Telemetry Unit (RCTU). This unit provides various types of

commands and telemetry. The ACIS hardware is commanded via high-level pulse commands to the ACIS

Power Supply and Mechanism Controller (PSMC) and by 16-bit serial digital commands to the ACIS

hardware serial port. In addition, commands to the ACIS software are contained within a series of 16-bit

serial command words, known as command packets, which are addressed to the ACIS software serial

port. For the purposes of this document, “Hardware commands” will refer to either high-level pulse

commands addressed to the PSMC, or serial digital commands addressed to the DPA hardware serial port.

“Software commands” will always refer to command packets addressed to the ACIS software serial

port.

The ACIS hardware provides engineering telemetry that is read by the spacecraft and placed in fixed places within

the spacecraft telemetry stream. The ACIS software produces telemetry as a stream of 32-bit words, packed and

placed into the spacecraft telemetry stream allocated for ACIS science telemetry. These packets may or may not be

separated by a variable number of fill bytes (0xb7), placed into the stream by the ACIS hardware when a packet is

not being transferred.

For details on the content and format of the ACIS hardware commands and telemetry, refer to the

ACIS Instrument Protocol and Command List (MIT-CSR 36-01410). For details on the content and

format of the ACIS software command and telemetry, refer to the ACIS IP&CL Software Structure

Definitions (MIT-CSR 36-53204.0204). For convenience, these definitions are summarized online in

“acisweb.mit.edu/acis/ipcl”.

In this document, all commands to send to ACIS will be written in the syntax accepted by the bcmd

command, a PERL script that translates ASCII input into a stream of binary commands and headers

suitable for repackaging, e.g., through the SOT/ACIS Command Generation Software (SACGS) functions

to create entries for the ACIS command tables used by the Observatory Control Center (OCC), or

through sendCmds to send to the ACIS engineering unit. The bcmd functions are illustrated in Appendix

B. This and other EGSE commands are listed in Appendix D and more fully described in on-line

manuals and in the “ACIS Test Tools” document MIT-CSR 36-55001 referenced in Table 1.1. bcmd

commands are written in structured ASCII text with optional comments, as illustrated in the following

example:

| start 58 te 4 | # start a timed exposure science run from the parameters in slot 4 |

The contents of all telemetry packets output by the BEP will be shown in this document in the format output by

the ltlm command whose function is to read BEP packet streams and translate them into ASCII.

The “start” command in this example will be acknowledged by ACIS with the following telemetry

packet:

| commandEcho[9] = { | |

| synch | = 0x736f4166 | |

| telemetryLength | = 6 | |

| formatTag | = 7 | # TTAG_CMD_ECHO |

| sequenceNumber | = 40276 | |

| arrival | = 0x17afd029 | |

| result | = 1 | # CMDRESULT_OK |

| startScience = { | | |

| commandLength | = 4 | |

| commandIdentifier | = 58 | |

| commandOpcode | = 14 | # CMDOP_START_TE |

| blockSlotIndex | = 4 | |

| } | | |

| } | | |

| |

| |

The names of UNIX commands and ACIS patches will be italicized and those of ACIS parameters will be shown in

monotype. Input to bcmd will be colored brown and output from ltlm will be green. The names given to packets,

commands, and their subfields are standardized across the ACIS ground system. Packets and their internal arrays

are also given numerical indices, as in the following example:

| deaHousekeepingData[3] = { | |

| synch | = 0x736f4166 | |

| telemetryLength | = 40 | |

| formatTag | = 11 | # TTAG_DEA_HOUSE |

| sequenceNumber | = 17733 | |

| deaBlockId | = 4132 | |

| commandId | = 18 | |

| bepTickCounter | = 0x2a92298e | |

| entries[0] = { | | |

| ccdId | = 10 | |

| queryId | = 0 | # DEAHOUSE_CNTL_RELAY |

| value | = 31 | # 0x001f |

| } | | |

| entries[1] = { | | |

| ccdId | = 10 | |

| queryId | = 1 | # DEAHOUSE_CNTL_ADC_TMP_BEP_PCB |

| value | = 2550 | # 0x09f6 |

| } | | |

| ... | | |

| } | | |

| |

where comments begin with “#” and, in this document, “...” implies that less important lines have been omitted

for clarity, especially in the first 4 fields of each packet: synch through sequenceNumber.

This document contains many examples of “keyword = value” pairs, either passed to bcmd or output from ltlm and

psci. We shall use two dots to indicate that a value will lie within a specified range, e.g., “fepId = 0..5”, and three

dots to indicate an array of values, e.g., “fepCcdSelect = n0...n5”, to represent integers n0, n1,

etc.

Section 3

Instrument Maintenance Activities

This section describes the various activities used to maintain the ACIS instrument software.

3.1 Starting the Software

This section describes how the ACIS instrument software is started. Before reading this section, the reader should

familiarize themselves with the discussion in Table A.1 in Appendix A of the internal status flags in each of the two

ACIS Back End Processors (BEPs).

A BEP can boot in one of five modes, as determined by the values of three bits in its Status Register,

two of which, BOOT_MOD and WARM_BOOT, are set by ground command and the third, WDOGRST, is set

when a “watchdog timer” expires, usually the result of some anomalous condition. See Table A.1 for

details.

Table 3.1: BEP Boot Modes

|

|

|

|

|

|

| Mode | Flag Values | Load from | Patches* | Pblocks | FEPs/DEAs

|

|

|

|

|

|

|

| Uplink

Boot | BOOT_MOD==1 | Uplink

Command

FIFO | Ignore | Ignore | Ignore |

|

|

|

|

|

|

| Power-On

Boot | WDOGRST==0

WARM_BOOT==0 | EEPROM | Delete | Copy

from

EEPROM | Assume

all

unpowered |

|

|

|

|

|

|

| Cold

Watchdog

Boot | WDOGRST==1

WARM_BOOT==0 | EEPROM | Delete | Copy

from

EEPROM | Assume

all

unpowered |

|

|

|

|

|

|

| Warm

Watchdog

Boot | WDOGRST==1

WARM_BOOT==1 | EEPROM | Ignore | Ignore | Ignore |

|

|

|

|

|

|

| Warm

Boot | WDOGRST==0

WARM_BOOT==1 | EEPROM | Apply | Ignore | Ignore |

|

|

|

|

|

|

| |

* Ignore leaves the patches in I-cache memory, but ignores them. Delete deletes them from I-cache and doesn’t apply them;

Apply leaves them in I-cache and applies them.

The BEP tests the three hardware bits in the order shown, i.e., if BOOT_MOD is 1, it will perform an Uplink Boot;

otherwise it will test WDOGRST and WARM_BOOT and proceed accordingly. The implications of these various modes will

be examined in the following sections.

3.1.1 Back End Processor Power-On

This section describes how to power-on a BEP in the ACIS Digital Processor Assembly (DPA). A BEP must be

powered up for the instrument to receive commands.

-

Description

-

On ACIS, there are two Back End Processors, (BEPs), a Side-A processor and a Side-B processor. The

Side-A BEP is powered by the Side-A DPA Power Supply in the PSMC, whereas the Side-B BEP is

powered by the Side-B DPA PSMC. Each BEP is powered by issuing a PSMC enable command to

the appropriate side, followed by a power-on command to that side. See Table 3.1 and Table B.5 in

Appendix B.3 for lists of PSMC power commands. When powered, the BEP hardware and software

will perform a power-on boot (see Section 3.1.3.1).

Since Side-A of the PSMC also supplies power to three of the Front End Processors (FEPs 0,1 and 2)

and the Side-B PSMC supplies power to the remaining three FEPs (3, 4 and 5), both BEP processors

are normally powered at the same time. However, only one BEP may be “active” at a time. At power-on,

the Side-A BEP is the “active” BEP, while the Side-B BEP’s processor is held in a reset state and

its external I/O logic is inactive. See Section 3.1.2 for a description on how to select the active BEP

and for warnings concerning FEP power when switching between BEPs. See Tables 3.2 and B.2 (in

Appendix B.2) for lists of commands affecting BEP status.

NOTE: If BEP-B is powered up, and BEP-A is not already powered, BEP-B will not be the selected

BEP, and the serial digital telemetry and bi-level telemetry from the DPA will float. Lab experience

has shown that the floating lines tend to a logical ’1’. See Section 3.1.2 for the procedure to activate

BEP-B.

-

Commands

-

Table 3.1 lists the commands issued to power-on the BEPs. See Section 3.2 for commands to power-off

the DPA’s BEPs. Also, see Section 3.1.3 for commands needed to enable and power on and off the

Detector Electronics Assembly.

Table 3.2: Power On Command Sequence

|

|

|

| Mnemonic | Command Type | Description

|

|

|

|

| Power Up DPA Side-A Power Supply

|

|

|

|

| 1DPPSAEN | Pulse to PSMC Side-A | Enable

(but

don’t

power

on)

the

PSMC

DPA

Side-A |

|

|

|

| 1DPPSAON | Pulse to PSMC Side-A | Power-On

the

PSMC

DPA

Side-A

Power |

|

|

|

| Power Up DPA Side-B Power Supply

|

|

|

|

| 1DPPSBEN | Pulse to PSMC Side-B | Enable

(but

don’t

power

on)

the

PSMC

DPA

Side-B |

|

|

|

| 1DPPSBON | Pulse to PSMC Side-B | Power-On

the

PSMC

DPA

Side-B

Power |

|

|

|

| |

Table 3.3: Power On Engineering Telemetry

|

|

|

|

| Mnemonic* | Telemetry Type | Value | Description

|

|

|

|

|

| While the BEPs are off and PSMC disabled

|

|

|

|

| 1DPPSAX | Serial

Digital | 0 | Verifies

that

the

DPA

A-side

Power

Supply

is

disabled. |

|

|

|

|

| 1DPPSBX | Serial

Digital | 0 | Verifies

that

the

DPA

B-side

Power

Supply

is

disabled. |

|

|

|

|

| 1DPPSA | Serial

Digital | 0 | Verifies

that

the

DPA

A-side

Power

Supply

is

off. |

|

|

|

|

| 1DPPSB | Serial

Digital | 0 | Verifies

that

the

DPA

B-side

Power

Supply

is

off. |

|

|

|

|

| 1TSERXT | SW

Serial

Digital | undefined | The

software

serial

digital

telemetry

out

of

a

BEP

while

powered

off

is

undefined,

however

lab

experience

shows

the

interface

almost

always

floats

to

1’s,

giving

8-bit

data

values

of

0xff |

|

|

|

|

| 1STAT[0..7]ST | HW

Bi-level | undefined | The

bi-level

telemetry

of

the

BEP

when

powered

off

is

undefined,

however,

lab

experience

shows

the

interface

almost

always

floats

to

1’s. |

|

|

|

|

| After a pair of PSMC DPA Enable commands have been issued

|

|

|

|

| 1DPPSAX | Serial

Digital | 1 | Verifies

that

the

DPA

A-side

Power

Supply

has

been

enabled |

|

|

|

|

| 1DPPSBX | Serial

Digital | 1 | Verifies

that

the

DPA

B-side

Power

Supply

has

been

enabled |

|

|

|

|

| After a pair of PSMC DPA Power-On commands have been issued

|

|

|

|

| 1DPPSA | Serial

Digital | 1 | Verifies

that

the

DPA

A-side

Power

Supply

has

been

turned

on. |

|

|

|

|

| 1DPPSB | Serial

Digital | 1 | Verifies

that

the

DPA

B-side

Power

Supply

has

been

turned

on. |

|

|

|

|

| 1TSERXT | SW

Serial

Digital | fill = 0xb7 | Once

a

BEP

is

powered

and

enabled

(side-A

defaults

to

enabled),

the

hardware

places

a

fill

pattern

into

the

software

serial

telemetry

stream.

This

fill

pattern

appears

whenever

the

software

is

not

transmitting

telemetry

packets. |

|

|

|

|

| 1STAT0ST | Bi-level:

bits

0-3 | variable | When

the

BEP

is

first

powered,

the

software

sets

the

bi-levels

to

0xf.

As

the

system

boots,

it

walks

the

bi-levels

through

a

series

of

values

so

that

if

the

instrument

gets

“stuck”,

the

ground

can

tell

where.

The

bi-level

value

sequence

is

described

in

more

detail

in

Section 3.1.3

and

Section 3.1.4.

Once

running,

the

Flight

Software’s

Housekeeping

Task

updates

these

bits

to

indicate

the

current

state

of

the

instrument. |

|

|

|

|

| 1STAT1ST | | variable | |

|

|

|

|

| 1STAT2ST | | variable | |

|

|

|

|

| 1STAT3ST | | variable | |

|

|

|

|

| 1STAT4ST | Bi-level:

BEP

Id | 0 (BEP-A) | If

BEP-A

is

powered

on

first,

it

will

be,

by

default,

the

selected

BEP

and

drive

the

bi-level

to

0. |

|

|

|

|

| 1STAT5ST | Bi-level:

CPU

Not

Reset | 1 | Since,

by

default,

BEP-A

is

not

held

in

a

reset

state

when

first

powered,

the

BEP

will

drive

this

bi-level

to

a

1. |

|

|

|

|

| 1STAT6ST | Bi-level:

FIFO

Not

Full | 1 | After

a

power-on,

the

BEP’s

command

FIFO

is

reset

by

the

hardware,

and

therefore

will

not

be

full,

but

instead

is

empty. |

|

|

|

|

| 1STAT7ST | Bi-level:

FIFO

Not

Empty | 0 | |

|

|

|

|

| |

* Hardware commands and telemetry mnemonics are described in the ACIS Instrument Protocol and Command List

(see Table:1.1.)

-

Engineering Telemetry

-

The following telemetry items in the engineering portion of the telemetry stream indicate when power is

applied to the BEPs. The following assume that BEP-A is being powered first.

-

Science Telemetry

-

When a BEP has power, and the software is not transmitting any telemetry packets, the hardware supplies a

single-byte fill pattern, 0xb7 (hexadecimal). Once the software is initialized after a power-on, it outputs a

BEP Startup Message telemetry packet, and then approximately once every 64 seconds outputs

a BEP Software Housekeeping telemetry packet. The Startup Message packet is described in

more detail in Section 3.1.3. The Software Housekeeping packet is described in more detail in

Section 3.4.3.

Table 3.4: Power On Science Telemetry

|

|

|

| Tag Field | Value | Description

|

|

|

|

| After the PSMC DPA Power-On command has been issued

|

|

|

|

If BEP-B is to be made active, a select command must also be issued (see Section 3.1.2)

|

|

|

|

| TTAG_STARTUP | – | After the BEP software is initialized, it issues a

BEP Startup Message packet. |

|

|

|

| TTAG_SW_HOUSE | – | Once running, the flight software emits 1 software

housekeeping packet every 64 seconds or so. |

|

|

|

| |

-

Warnings

-

-

1.

- Power Reset of Tables

A power-on will reset the state of the all hardware within ACIS, and reset all internal software

structures. Any code, tables and data loaded into RAM will be lost.

-

2.

- Power Reset of Uplink Flag

If the instrument was in a “load-from-uplink” state prior to being powered-off, the state of

“load-from-uplink” flag will be lost. When the instrument is subsequently powered on, it will load code

from its EEPROMs and execute the loaded code.

-

3.

- BEP Select Confusion

If BEP-B is powered on and selected while BEP-A is off, and then BEP-A is powered on, both BEPs

will be selected and will attempt to drive the telemetry interface. This will not hurt the hardware, but

will make software telemetry impossible to understand. A “Select BEP” command to choose either A

or B at this point will solve the problem.

3.1.2 Selecting which BEP is active

This section describes how to select which BEP should be active, and drive the interface hardware.

-

Description

-

By default, after a power-on, both BEP-A and BEP-B will assume that the active BEP is BEP-A.

To select BEP-B, one must explicitly issue a hardware serial digital command to select it. In order to

avoid confusion, and reduce the possibility of problems, it is recommended that a select command be

issued whenever one or both BEPs are first powered on. (NOTE: see Warnings concerning FEP power

when selecting BEPs). Whenever a BEP is de-selected, its processor is held in a reset state and the

software on the BEP is halted. If the BEP is then selected, the reset is released, and the BEP software

will proceed to boot and run.

-

Commands

-

The following are the commands issued to select a particular BEP.

Table 3.5: BEP Selection Commands

|

|

|

|

| Mnemonic | Command Type | Value | Description

|

|

|

|

|

| Select BEP-A

|

|

|

|

| 1BSELICL | HW Serial Digital | v=0 | Select BEP-A by issuing the Select BEP command

with data bit 0 (v) set to 0. |

|

|

|

|

| Select BEP-B

|

|

|

|

| 1BSELICL | HW Serial Digital | v=1 | Select BEP-B by issuing the Select BEP command

with data bit 0 (v) set to 1. |

|

|

|

|

| |

-

Engineering Telemetry

-

The currently selected BEP is indicated by a bi-level in the engineering telemetry (see Table 3.6).

Table 3.6: Selected BEP in Engineering Telemetry

|

|

|

|

| Mnemonic | Command Type | Value | Description

|

|

|

|

|

| When BEP-A is the selected BEP:

|

|

|

|

| 1STAT4ST | Bi-level: BEP Id | 0 | If BEP-A is selected, this bi-level will have a value

of 0. |

|

|

|

|

| When BEP-B is the selected BEP:

|

|

|

|

| 1STAT4ST | Bi-level: BEP Id | 1 | If BEP-B is selected, this bi-level will have a value

of 1. NOTE: If the active BEP is powered off at

the PSMC, all bilevels will float to ‘1’, which may

lead to confusion under some conditions. |

|

|

|

|

| |

-

Science Telemetry

-

If the chosen BEP is not already selected, then the select command releases the BEP’s reset

line, causing the instrument software to load and run. Depending on the state of the BEP’s

Boot Modifier Flag at the time of the select command is received, the instrument software’s

bootstrap loader will either (a) load code from EEPROM (see Section 3.1.3) and will produce its

standard Startup Message telemetry packet, and subsequent Software Housekeeping telemetry

packets, or (b) will load code from a series of software serial command packets (Section 3.1.4),

which may or may not produce any science telemetry, depending on what code is loaded and

run.

-

Warnings

-

-

1.

- BEP already selected

If the BEP is already selected, it will not be re-booted.

-

2.

- BEP not already selected

If the BEP is not currently the selected BEP, it will be held in a reset state. Once selected, the BEP will

behave depending on the most recently received “halt bep” or “run bep” command (i.e. the newly

selected BEP with either start in a reset state or reboot accordingly).

-

3.

- Both BEP-A and -B are selected

If BEP-A is powered on, or power-cycled while BEP-B is selected and running, BEP-A will assume

that it is selected. This will cause contention and confusion on the telemetry interface. To correct the

problem, re-issue the most recent select command after powering on BEP-A. To avoid the problem,

issue halt bep and select bep a commands prior to powering on BEP-A.

-

4.

- Neither BEP-A nor -B are selected

If BEP-A is powered on while BEP-B is powered off, and is then told that BEP-B is selected, no BEP

will be driving the interfaces.

-

5.

- FEPs may be held “on”

The BEP-A and BEP-B can both be commanded to enable and disable power to the FEPs. If both

BEPs are powered and the previously selected BEP has left power enabled to some of the FEPs, the

currently selected BEP will not be able to power-off those FEPs. This state is not harmful for the

hardware, but may lead to confusion in subsequent observations. It will stay this way until either

the previous BEP is made active again and commanded to power down those FEPs, or the PSMC is

commanded to cycle the power on that BEP and its 3 associated FEPs. Therefore, be very sure to

power down all FEPs before switching BEPs. See Section 3.3.2 for more detail.

3.1.3 Loading from EEPROM

Each ACIS Back End Processor is capable of loading its software either from its Read-Only-Memory, or from its

uplink channel via software serial commands. This section describes the former.

3.1.3.1 Power-On Boot

-

Description

-

When a Back-End Processor (BEP) is powered on and selected, it executes a bootstrap loader

residing within its Read-Only Memory (EEPROM). A special EGSE cable was required to enable the

“Electrically Erasable and Programmable” function of this memory, and was removed prior to launch.

This loader copies the bulk of the instrument software from the EEPROM into the BEP’s RAM, and

transfers control to the loaded code. The loaded code detects that the instrument has been started by

a power on and as a result takes the following actions:

-

1.

- Copies the bulk of code and initialized data from EEPROM into I-cache and D-cache RAM.

-

2.

- Resets the Patch List to “empty”.

-

3.

- Copies Parameter Blocks (Te, Cc, 2d, 1d, Dea) from EEPROM into RAM (see Appendix I).

-

4.

- Copies Bad Pixel and Column Maps from EEPROM into RAM.

-

5.

- Copies Huffman Tables from EEPROM into RAM.

-

6.

- Copies System Configuration Settings from EEPROM into RAM.

-

7.

- Issues a Startup Message telemetry packet.

-

8.

- All DEA Video boards will be powered off (as per the default EEPROM System Configuration

Table settings).

-

9.

- All Front End Processors (FEP) will be assumed to be powered off (as per the default EEPROM

System Configuration Table settings). Note that after a power anomaly, the operator cannot

assume that all FEPs are unpowered and must explicitly power on all FEPs and then command

them to their desired states.

-

10.

- Focal Plane temperature will be reset to its default EEPROM System Configuration Table value.

-

Commands

-

To power on and run Side-A BEP:

| IP&CL syntax | bcmd syntax | Command Description

|

|

|

|

| 1DPPSAEN | enable dpa a | Enable Side-A DPA Power Supply |

| 1DPPSAON | poweron dpa | Power-On Side-A DPA Power Supply |

| 1BSELICL(v=0) | select bep a | Select Side-A BEP ensuring no contention with BEP-B. |

| |

To power on and run Side-B BEP:

| IP&CL syntax | bcmd syntax | Command Description

|

|

|

|

| 1DPPSBEN | enable dpa b | Enable Side-B DPA Power Supply |

| 1DPPSBON | poweron dpa b | Power-On Side-B DPA Power Supply |

| 1BSELICL(v=1) | select bep b | Select Side-B BEP |

| |

-

Engineering Telemetry

-

Command Verifiers

| 1DPPSAX | 0..1 | Reports

if

DPA

Power

Supply

A

is

enabled |

| 1DPPSA | 0..1 | Reports

if

DPA

Power

Supply

A

is

on |

| 1DPPSBX | 0..1 | Reports

if

DPA

Power

Supply

B

is

enabled |

| 1DPPSB | 0..1 | Reports

if

DPA

Power

Supply

B

is

on |

| 1STAT4ST | 0 | indicates

BEP-A

is

selected, |

| | 1 | indicates

BEP-B

is

selected |

| | | (NOTE:

See

Warnings

in

Section 3.1.2) |

| |

|

Boot Bi-level Sequence

| LED_BOOT_RESET | (1,1,1,1) | BEP

has

just

reset |

| LED_RUN_PATCH | (1,0,0,1) | Resetting

patch

list |

| LED_RUN_STARTUP | (1,0,0,0) | After

an

initial

64

second

wait,

the

BEP’s

Software

Housekeeping

task

will

alternate

the

bi-levels

between

two

values

every

64

seconds

indicating

whether

or

not

a

science

run

is

in

progress,

and

that

the

BEP

was

not

restarted

due

to

a

watchdog

reset.

If

a

science

run

is

not

in

progress,

the

bi-levels

will

alternate

between: |

| LED_RUN_IDLE_A | (0,1,1,0) | |

| LED_RUN_IDLE_B | (0,1,1,1) | |

| |

|

If a science run is activated, the bi-levels will change to:

| LED_RUN_SCIENCE_A | (0,1,0,0) | |

| LED_RUN_SCIENCE_B | (0,1,0,1) | |

| |

-

Science Telemetry

-

Startup Message from Power On Boot

| bepStartupMessage[n] = { | |

| synch | = 0x736f4166 | # Packet synch word |

| telemetryLength | = 7 | # Packet length in words |

| formatTag | = 8 | # TTAG_STARTUP |

| sequenceNumber | = n | # Packet sequence number |

| bepTickCounter | = n | # (n < 10) BEP interrupt clock value |

| version | = 11 | # BEP software version in EEPROM |

| lastFatalBepTickCounter | = n | # BEP interrupt count at last fatal error |

| lastFatalCode | = n | # Stored BEP interrupt code (see Table 3.15) |

| watchdogFlag | = 0..1 | # if 1, SEU or hardware error |

| patchValidFlag | = 0..1 | # if 0, SEU or hardware error |

| configFlag | = 0..1 | # if 0, SEU or hardware error |

| parametersFlag | = 0..1 | # if 0, SEU or hardware error |

| warmBootFlag | = 0..1 | # if 1, SEU or H/W error |

| } | | |

| |

| |

Software Housekeeping

| swHousekeeping[n] = { | |

| ... | | |

| formatTag | = 10 | # TTAG_SW_HOUSE |

| startingBepTickCounter | = n | # Starting BEP timer value |

| endingBepTickCounter | = n+640 | # Ending BEP timer value |

| statistics[0] = { | | |

| swStatisticId | = 0 | # SWSTAT_VERSION |

| count | = 1 | # Number of reports |

| value | = 11 | # Most recent reported value |

| } | | |

| statistics[1] = { | | |

| swStatisticId | = 3 | # SWSTAT_TIMERCB_INVOKE |

| count | = 640 | # Number of reports (~10 per second) |

| value | = 0 | # Most recent reported value |

| } | | |

| } | | |

| |

| |

-

Warnings

-

-

1.

- Power-On Boot is always a Cold Boot

A power-on boot resets the BEP’s hardware flags, such as the Warmboot flag, and the Load-from-Uplink

flag, making it impossible to perform a Warm Boot or Load-from-Uplink Boot using just a power-on

command sequence. See Section 3.1.4 for a description of how to perform a Load-from-Uplink Boot,

and Section 3.1.3.3 for a description of a Warm Boot.

-

2.

- “As-launched” settings (including temperature control)

All Patches are lost and all Parameter Blocks, System Configuration Settings, and Huffman

Compression Tables will be reset to their “as-launched” values (see Appendix I). Note: This affects

power-consumption of the instrument, the focal-plane temperature control set point, and sets all 12-bit

Analog to Digital Converter (ADC) channels reported in DEA housekeeping to 8-bit (coarse) mode.

-

3.

- Memory Decay

Don’t count on any unused portions of BEP or FEP memory remaining intact. The powered-off static

RAM memory will “decay” over time.

-

4.

- See Warnings in Section 3.1.2

-

5.

- “Stuck” Bi-level Values

The initial boot bi-level sequence will change faster than the sample rate of the telemetry system.

Unless something goes wrong, don’t expect to see every code in the sequence as the instrument comes

up. However, if the bi-level values “stick” to the following values for more than one science telemetry

frame, or codes persist that are not listed, there is probably a problem with the instrument or command

sequence to the instrument:

| LED_BOOT_RESET | (1,1,1,1) | BEP has just reset |

| LED_RUN_PATCH | (1,0,0,1) | Copying patches or resetting patch list |

| |

If the following bi-level code “sticks” for more than 64 seconds, there may also be a problem:

| LED_RUN_STARTUP | (1,0,0,0) | Starting the multi-tasking executive |

| |

In addition, software patches may set the bi-levels to special values in order to signal to Chandra’s On-Board

Computer that some action should be taken. Currently, the following patches use special (unique)

combinations:

|

|

|

|

| Patch | Mnemonic | Value | Meaning

|

|

|

|

|

| txings | LED_BOOT_SPARE1 | (1,1,0,1) | The threshold crossing detector has tripped |

|

|

|

|

| deahktrip | LED_BOOT_SPARE2 | (1,1,1,0) | One or more DPA temperature channels has

exceeded its red limits |

|

|

|

|

| |

3.1.3.2 Cold Boot

-

Description

-

Cold Boots are performed in order to reset and re-initialize a BEP into an “as-launched” state,

without resorting to cycling the power. In order to perform a cold boot, the desired BEP must be

powered-on, and selected, with its Load-from-Uplink flag cleared (default condition after power-on),

and its Warmboot flag cleared (default condition after power-on). It then must receive a BEP Halt

command, followed by a BEP Run command. This will cause the BEP CPU to start executing the

loader in its EEPROM. From then on, the boot process of the BEP appears just as a power-on boot.

The loader and startup software will reset the Patch List, and reload the default tables from EEPROM.

Like a Power-On boot, a cold boot of the BEP:

-

1.

- Copies the bulk of code and initialized data from EEPROM into I-cache and D-cache RAM

-

2.

- Resets the Patch List to “empty”

-

3.

- Copies Parameter Blocks (Te, Cc, 2d, 1d, Dea) from EEPROM into RAM (see Appendix I)

-

4.

- Copies Bad Pixel and Column Maps from EEPROM into RAM

-

5.

- Copies Huffman Tables from EEPROM into RAM

-

6.

- Copies System Configuration Settings from EEPROM into RAM

-

7.

- Issues a Startup Message telemetry packet

-

8.

- All DEA Video boards and Front End Processors will be powered off (as per the default EEPROM

System Configuration Table settings)

-

9.

- All Front End Processors (FEP) will be powered off, as per the default EEPROM System

Configuration Table settings, unless held on by the other BEP (see Section 3.3.2)

-

10.

- Focal Plane temperature will be reset to its default EEPROM System Configuration Table value

-

Commands

-

| IP&CL syntax | bcmd syntax | Command Description

|

|

|

|

| 1BMODIBM (v=0) | set bootmodifier off | Enable boot from EEPROM mode |

| 1WRMBTSB (v=0) | set warmboot off | Enable cold boot mode |

| 1RSETIRT (v=1) | halt bep | Stop the active BEP |

| 1RSETIRT (v=0) | run bep | Restart and reboot the active BEP |

| |

-

Engineering Telemetry

-

Boot Bi-level Sequence (for detail, refer to Engineering Telemetry in Section 3.1.3.1)

| LED_BOOT_RESET |

| LED_RUN_PATCH |

| LED_RUN_STARTUP |

| LED_RUN_IDLE_A |

| LED_RUN_IDLE_B |

| LED_RUN_SCIENCE_A |

| LED_RUN_SCIENCE_B |

|

| |

-

Science Telemetry

-

∙ Startup Message

| bepStartupMessage[n] = { | |

| ... | | |

| formatTag | = 8 | # TTAG_STARTUP |

| bepTickCounter | = n | # (n < 10) BEP interrupt clock value |

| version | = 11 | # BEP software version in EEPROM |

| lastFatalBepTickCounter | = n | # BEP interrupt count at last fatal error |

| lastFatalCode | = n | # Stored BEP interrupt code (see Table 3.15) |

| watchdogFlag | = 0..1 | # =1 if watchdog timer expired |

| patchValidFlag | = 0..1 | # * =0 if patch list invalid |

| configFlag | = 0..1 | # * =0 if config table invalid |

| parametersFlag | = 0..1 | # * =0 if pblocks invalid |

| warmBootFlag | = 0..1 | # =1 if BEP warm booted |

| } | | |

| |

| |

NOTE: if any of the 3 starred fields is ‘0’, suspect a BEP hardware error or single-event upset (SEU) or

telemetry corruption.

∙ Software Housekeeping

| swHousekeeping[n] = { | |

| ... | | |

| formatTag | = 10 | # TTAG_SW_HOUSE |

| startingBepTickCounter | = n | # Starting BEP timer value |

| endingBepTickCounter | = n+640 | # Ending BEP timer value |

| statistics[0] = { | | |

| swStatisticId | = 0 | # SWSTAT_VERSION |

| count | = 1 | # Number of reports |

| value | = 11 | # Most recent reported value |

| } | | |

| statistics[1] = { | | |

| swStatisticId | = 3 | # SWSTAT_TIMERCB_INVOKE |

| count | = 640 | # Number of reports (~10 per second) |

| value | = 0 | # Most recent reported value |

| } | | |

| } | | |

| |

| |

-

Warnings

-

-

1.

- A Cold Reboot may occur on receipt of a BEP Select Command

If a BEP is running, i.e., not in the RESET state, and the other BEP is selected, the latter will

immediately reboot in the mode determined by the values of its Load-from-Uplink, Watchdog, and

Warmboot flags. For this reason, prior to switching BEPs, it is good practice to command the active

BEP into the RESET state before selecting the other BEP.

-

2.

- “As-launched” settings (including temperature control)

All Patches, Parameter Blocks, System Configuration Settings, and Huffman Compression Tables will

be reset to their “as-launched” values (see Appendix I). Note: This affects power-consumption of the

instrument and the focal-plane temperature control set point (see Section 3.3.6 and Appendix E).

-

3.

- DEA Power-Up Issues

See Warnings #4 and #5 to Section 3.1.3.3 and Section 3.3.6.

-

4.

- Preserved Memory

Unused portions of BEP memory will remain intact.

-

5.

- “Stuck” Bi-level Values

The initial boot bi-level sequence will change faster than the sample rate of the telemetry system.

Unless something goes wrong, don’t expect to see every code in the sequence as the instrument comes

up. However, if the bi-level values “stick” to the following values for more than one science telemetry

frame, or codes persist that are not listed, there is probably a problem with the instrument or command

sequence to the instrument:

| LED_BOOT_RESET | (1,1,1,1) | BEP has just reset |

| LED_RUN_PATCH | (1,0,0,1) | Copying patches or resetting patch list |

| |

If the following bi-level code “sticks” for more than 64 seconds, there may also be a problem:

| LED_RUN_STARTUP | (1,0,0,0) | Starting the multi-tasking executive |

| |

3.1.3.3 Warm Boot

-

Description

-

A Warm Boot is used to reset a BEP’s hardware, re-load its code and data from EEPROM and install its

patch list while attempting to maintain the already loaded configuration tables and parameter blocks.

A Warm Boot retains the BEP’s Patch List, Parameter Blocks, etc. To issue a Warm Boot, the BEP

must be powered on and selected, with its Load-from-Uplink flag de-asserted, but its warmBootFlag and

its watchdogFoot flags bothflag in an asserted state. Upon receipt of a Halt BEP command followed

by a Run BEP command, the BEP hardware will reset and invoke the loader software in its EEPROM.

This loader copies the bulk of the instrument software from the EEPROM into the BEP’s RAM, and

transfers control to the loaded code. The loaded code detects that the instrument warmBootFlag flag

is asserted, and installs the Patch List nodes, overwriting the code and data areas specified by the

nodes with the data stored in the patch nodes. The startup software then issues a bepStartupMessage

telemetry packet.

A Warm Boot of the BEP:

-

1.

- Copies the bulk of code and initialized data from EEPROM into I-cache and D-cache RAM.

-

2.

- Installs the patches, overwriting code and data specified by the nodes in the Patch List with the

data contained in the Patch List nodes.

-

3.

- Issues a Startup Message telemetry packet, indicating the integrity of the patch list, parameter

blocks and system configuration table. NOTE: Since the system configuration table controls the

focal-plane temperature and FEP and DEA power settings, if the table has been corrupted,

the startup code will restore the default system configuration table from EEPROM into RAM,

overwriting the corrupted copy.

-

4.

- The initialization code for the DEA will reset the DEA Interface Controller board. This

will have the effect of powering off the video boards. Within a few seconds, however, the

System Configuration Task will restore power to those boards indicated in the preserved system

configuration table (i.e. those boards that were on prior to the warm boot, will be re-powered,

provided the configuration table checksum is valid (see Warning #4, below).

-

5.

- The BEP will also issue a hard reset to the DEA (PULSE_DEARST), which will cause its A-to-D

converters to recalibrate and the focal plane temperature controller to reactivate. For details, see

Warning #4 of Section 3.3.3.

-

6.

- The hardware reset of the BEP will cause a reset of the Front End Processors (FEP), but won’t

reset the FEP power settings. FEPs that were powered prior to the reset will remain powered,

but will be held in reset state until a science run is started, or until they are powered off via

subsequent cold boots or “Change System Configuration” commands (see Section 3.3.2).

-

Commands

-

| IP&CL syntax | bcmd syntax | Command Description

|

|

|

|

| 1BMODIBM (v=0) | set bootmodifier off | Set the Bootmodifier flag off |

| 1WRMBTSB (v=1) | set warmboot on | Set the Warmboot flag on |

| 1RSETIRT (v=1) | halt bep | Halt the active BEP |

| 1RSETIRT (v=0) | run bep | Restart the active BEP |

| |

-

Engineering Telemetry

-

Boot Bi-level Sequence (for detail, refer to Engineering Telemetry in Section 3.1.3.1)

| LED_BOOT_RESET |

| LED_RUN_PATCH |

| LED_RUN_STARTUP |

| LED_RUN_IDLE_A |

| LED_RUN_IDLE_B |

| LED_RUN_SCIENCE_A |

| LED_RUN_SCIENCE_B |

|

| |

-

Science Telemetry

-

∙ Startup Message

The following packet is received after a successful warm boot. If valid patches had been loaded, they will

typically set the version field to a value denoting the patch level (see column “Ver” of Table F.2). Otherwise,

version will be 11, the value set from the EEPROM code.

| bepStartupMessage[n] = { | |

| ... | | |

| formatTag | = 8 | # TTAG_STARTUP |

| bepTickCounter | = n | # n < 10 or SEU or H/W error |

| version | = n | # ≠11 indicates patched or SEU or H/W error |

| lastFatalBepTickCounter | = n | # BEP interrupt count at last fatal error |

| lastFatalCode | = n | # Stored BEP interrupt code (see Table 3.15) |

| watchdogFlag | = 0 | # = 1 if watchdog boot or SEU or H/W |

| patchValidFlag | = 0 | # = 0 if patch list corrupted |

| configFlag | = 0 | # = 0 if config table corrupted |

| parametersFlag | = 0 | # = 0 if parameter blocks corrupted |

| warmBootFlag | = 1 | # = 0 if SEU or H/W error |

| } | | |

| |

| |

∙ Software Housekeeping

| swHousekeeping[n] = { | |

| ... | | |

| formatTag | = 10 | # TTAG_SW_HOUSE |

| startingBepTickCounter | = n | # Starting BEP timer value |

| endingBepTickCounter | = n+640 | # Ending BEP timer value |

| statistics[0] = { | | |

| swStatisticId | = 0 | # SWSTAT_VERSION |

| count | = 1 | # Number of reports |

| value | = 11 | # or patched or SEU or H/W error |

| } | | |

| statistics[1] = { | | |

| swStatisticId | = 3 | # SWSTAT_TIMERCB_INVOKE |

| count | = 640 | # Number of reports (≈10/second) |

| value | = 0 | # Most recent reported value |

| } | | |

| } | | |

| |

| |

If an error is encountered restoring DEA video board power then expect an additional statistics item (see

below) in the housekeeping packet, where the value field reports the video board ID (0..9) in its most

significant 16 bits and the internal DEA error code (see Table B.9 in Appendix B.4) in its least significant

16.

| statistics[2] = { | |

| swStatisticId | = 53 | # SWSTAT_DEABOARD_ERROR |

| count | = n | # Number of reports |

| value | = v | # v = (boardId << 16) | deaErr |

| } | | |

| |

| |

-

Warnings

-

-

1.

- Warm Reset via the BEP Select command

If an un-selected BEP is selected, its Load-from-Uplink is de-asserted, but its Warmboot flag is asserted,

the BEP will perform a warm boot.

-

2.

- Retained Parameter Blocks

All Patches, Parameter Blocks, and Huffman Compression Tables are retained.

-

3.

- Retained/Corrupted System Configuration

The System Configuration Table will be retained if its checksum is intact. If corrupted, however, the

System Configuration Table will be overwritten by the default contained in EEPROM.

-

4.

- Power-cycled DEA Video Boards

If the System Configuration Table is intact, the DEA Video boards that were powered prior to the

reboot will be reset. If this is the first reboot since the PSMC last powered-up, the DEA interface

board may not have been fully initialized (see Section 3.3.3). A second BEP reboot will ensure that it

is.

-

5.

- Cycled Focal Plane Temperature Control

If the System Configuration Table is intact, the DEA focal-plane temperature control set point will be

set to 0 (due to the interface board reset), and then to the value it had prior to the reset.

-

6.

- Reset FEPs

If the System Configuration Table is intact, FEP boards that were powered prior to the reset will

remain powered, but will be held in a reset state.

-

7.

- Preserved Memory

Unused portions of BEP memory will remain intact.

-

8.

- “Stuck” Bi-level Values

The initial boot bi-level sequence will change faster than the sample rate of the telemetry system.

Unless something goes wrong, don’t expect to see every code in the sequence as the instrument comes

up. However, if the bi-level values “stick” to the following values for more than one science telemetry

frame, or codes persist that are not listed, there is probably a problem with the instrument or command

sequence to the instrument:

| LED_BOOT_RESET | (1,1,1,1) | BEP has just reset |

| LED_RUN_PATCH | (1,0,0,1) | Copying patches or resetting patch list |

| |

If the following bi-level code “sticks” for more than 64 seconds, there may also be a problem:

| LED_RUN_STARTUP | (1,0,0,0) | Starting the multi-tasking executive |

| |

Certain software patches also set software bilevels to special values so that the Chandra On-Board Computer

can detect them and take some preset action. For details, see Warning 5 on Page 37.

3.1.3.4 Watchdog Reset

-

Description

-

When a BEP’s watchdog timer expires, the hardware sets a watchdog-reboot flag and issues a hardware

reset. This may be caused by a task lockup in the BEP, or by a trapped fatal error condition, in which

the recovery code uses the watchdog timer to reset the BEP. Once the BEP reboots, the loader in

the BEP’s EEPROM is invoked. If the Load-from-Uplink flag is de-asserted, the loader copies code

and data from EEPROM into RAM, and invokes the loaded startup software. The startup software

checks the state of the Warmboot flag, and if asserted, it performs a warm-reboot sequence, except

that it skips the step that installs the patches. If the Warmboot flag is de-asserted, the boot-sequence

is identical to that of a cold-reboot (see Section 3.1.3.2). The ground can detect the occurrence of a

Watchdog reboot via the Startup Message telemetry packet, and via the bi-level telemetry items.

A Warm Watchdog Reset of the BEP:

-

1.

- Copies the bulk of code and initialized data from EEPROM into I-cache and D-cache RAM.

-

2.

- Skips the installation of the patches (NOTE: Although the patches aren’t applied to the code and

data in RAM, the patch list will remain intact).

-

3.

- Issues a Startup Message telemetry packet, indicating that there was a watchdog reboot, and

indicating the integrity of the patch list, parameter blocks and system configuration table. NOTE:

Since the system configuration table controls the focal-plane temperature and FEP and DEA

power settings, if the table has been corrupted, the startup code will restore the default system

configuration table from EEPROM into RAM, overwriting the corrupted copy.

-

4.

- The initialization code for the DEA will reset the DEA Interface Controller board. This

will have the effect of powering off the video boards. Within a few seconds, however, the

System Configuration Task will restore power to those boards indicated in the preserved system

configuration table (i.e. those boards that were on prior to the warm boot, will be re-powered).

-

5.

- The hardware reset of the BEP will cause a reset of the Front End Processors (FEP), but won’t

reset the FEP power settings. FEPs that were powered prior to the reset will remain powered,

but will be held in reset state until a science run is started, or until they are power-cycled via a

pair of “Change System Configuration” commands (see Section 3.3.2).

-

Commands

-

None (although the crash may be the result of an earlier command).

-

Engineering Telemetry

-

Boot Bi-level Sequence

| LED_BOOT_RESET | (1,1,1,1) | BEP has just reset |

| LED_RUN_PATCH | (1,0,0,1) | Copying patches |

| LED_RUN_STARTUP | (1,0,0,0) | Starting the multi-tasking executive |

| |

|

After an initial 64 second wait, the BEP’s Software Housekeeping task will alternate the bi-levels between two

values every 64 seconds indicating that no science runs are in progress, and that the BEP was restarted due to

a watchdog reset:

| LED_WD_IDLE_A | (0,0,1,0) |

| LED_WD_IDLE_B | (0,0,1,1) |

| |

If a science run is activated, the bi-levels will change to:

| LED_WD_SCIENCE_A | (0,0,0,0) |

| LED_WD_SCIENCE_B | (0,0,0,1) |

| |

-

Science Telemetry

-

If the Watchdog expiration is due to a caught Fatal Error, the BEP will issue a Fatal Error Message telemetry

packet, (provided the processor is still capable of forming and queueing the request), and then force a

watchdog timer expiration:

∙ Fatal Message

| fatalMessage[n] = { | |

| ... | | |

| formatTag | = 8 | # TTAG_FATAL |

| bepTickCounter | = n | # BEP tick on detection of error |

| fatalCode | = n | # BEP interrupt code (see Table 3.15) |

| fatalValue | = n | # meaning depends on fatalCode |

| } | | |

| |

| |

∙ Startup Message

| bepStartupMessage[n] = { | |

| ... | | |

| formatTag | = 8 | # TTAG_STARTUP |

| bepTickCounter | = n | # n < 10 or SEU or H/W error |

| version | = 11 | # or patched or SEU or H/W error |

| lastFatalBepTickCounter | = n | # BEP interrupt count at last fatal error |

| lastFatalCode | = n | # Stored BEP interrupt code (see Table 3.15) |

| watchdogFlag | = 1 | # or not watchdog or SEU or H/W |

| patchValidFlag | = 0 | # = 0 if patch list corrupted |

| configFlag | = 0 | # = 0 if config table corrupted |

| parametersFlag | = 0 | # = 0 if parameter blocks corrupted |

| warmBootFlag | = 0..1 | # = 0 if (coldboot) or 1 (warmboot) |

| } | | |

| |

| |

∙ Software Housekeeping

| swHousekeeping[n] = { | |

| ... | | |

| formatTag | = 10 | # TTAG_SW_HOUSE |

| startingBepTickCounter | = n | # Starting BEP timer value |

| endingBepTickCounter | = n+640 | # Ending BEP timer value |

| statistics[0] = { | |

| swStatisticId | = 0 | # SWSTAT_VERSION |

| count | = 1 | # Number of reports |

| value | = 11 | # or patched or SEU or H/W error |

| } | | |

| statistics[1] = { | |

| swStatisticId | = 3 | # SWSTAT_TIMERCB_INVOKE |

| count | = 640 | # Number of reports (≈10/second) |

| value | = 0 | # Most recent reported value |

| } | | |

| } | | |

| |

| |

If an error is encountered restoring DEA video board power then expect an additional statistics item (see

below) in the housekeeping packet, where the value field reports the video board ID (0..9) in its most

significant 16 bits and the internal DEA error code (see Table B.9 in Appendix B.4) in its least significant

16.

| statistics[2] = { | |

| swStatisticId | = 53 | # SWSTAT_DEABOARD_ERROR |

| count | = n | # Number of reports |

| value | = v | # v = (boardId << 16) | deaErr |

| } | | |

| |

| |

-

Warning

-

-

1.

- Cold Watchdog Boot

If the Warmboot flag is de-asserted when the watchdog timer expires, the system will perform a cold

boot, resetting the patch list, parameter blocks, bad pixel maps, etc. See Warnings in Section 3.1.3.2.

-

2.

- Warm Watchdog Boot with No Patches

If the Warmboot flag is asserted when the watchdog timer expires, the system will perform a warm

boot, except the patch list will not be installed. This could possibly raise compatibility issues with the

retained tables, if format changes were introduced that relied on the patches being installed, or worse,

a hardware problem work-around not being installed. Also, consider Warnings in Section 3.1.3.3.

-

3.

- Power off in-use FEP

The most common causes of Watchdog resets in the lab have been (a) bad patches, and (b)

FATAL_INTR_FEP_BUS_ERROR fatal errors due to accessing a FEP when its power is off. This can happen

if one powers off a FEP while it is being used in a science run.

-

4.

- Startup Message Info

In the Startup Message of the current version of the instrument software, the lastFatalCode field

contains the BEP tick counter of the most recent Fatal Error Message.

-

5.

- Recovery from Watchdog Boot

To recover from a Watchdog reset while preserving loaded patches, assuming the Patch List is not the

cause, issue a Halt BEP/Run BEP command sequence to cause a normal Warmboot of the BEP.

-

6.

- No looping Watchdogs

The hardware prevents looping Watchdog resets from locking up the instrument. After an initial

Watchdog reset, the hardware prevents subsequent watchdog timer expirations, including those caused

by a software Fatal Error, from resetting the BEP. An intervening commanded reset (or power-on

reset), is required to reenable watchdog resets.

3.1.4 Loading from Uplink

-

Description

-

The Load-from-Uplink feature of ACIS allows a maintainer to load arbitrary software into a Back

End Processor using the software serial-digital command channel. In order to load the BEP, one

must first assert the Load-from-Uplink flag, and then reset the BEP (Halt BEP/Run BEP). The

hardware transfers control to the loader software in the BEP’s EEPROM. The loader detects that

the Load-from-Uplink flag is asserted, and waits for a “Start Upload” command packet followed by

zero or more “Continue Upload” command packets. Once the entire load is copied from the uplinked

packets into the BEP’s RAM, the loader invokes the loaded software. Once running, the loaded code

has control of the instrument, and is responsible for all subsequent software command processing (if

any) and telemetry production (if any).

If the loader receives an unrecognized command packet, it will discard the packet, and re-start the

load, waiting for an initial “Start Upload” command packet.

If the loader receives a new “Start Upload” command packet in the middle of an existing load, the

loader will stop the current load (leaving what was already copied into RAM intact) and start the new

load. This behavior can be used to perform scatter loads into RAM (see Section 5.9).

-

Commands

-

| IP&CL syntax | bcmd syntax | Command Description

|

|

|

|

| 1BMODIBM (v=1) | set bootmodifier on | Set the Bootmodifier flag on |

| 1RSETIRT (v=1) | halt bep | Halt the active BEP |

| 1RSETIRT (v=0) | run bep | Restart the active BEP |

| |

∙ Start Uplink

Begin by issuing a start command, which has the following content in bcmd format:

| start n uplink loadAddress totalCount executeAddress { | | |

| word1 word2 ... | | |

| } | | |

| |

| |

where a totalCount of 32-bit words are to be loaded into BEP memory starting at loadAddress and then

executed, starting at executeAddress. If the number of words actually specified, i.e., word1, word2, etc., is

less than totalCount, the BEP will not reboot but wait to expect additional start or continue

commands.

∙ Continue Uplink

| continue n uplink { | | # CMDOP_CONTINUE_UPLOAD |

| word1 word2 ... | | |

| } | | |

| |

| |

Once totalCount words have been loaded, either from start or continue, BEP execution will begin at the

most recently supplied executeAddress. Once the program has been loaded and started, it is responsible for

processing subsequent software serial commands (if any).

-

Engineering Telemetry

-

Boot Bi-level Sequence

| LED_BOOT_RESET | (1,1,1,1) | BEP has just reset |

| LED_BOOT_UPLINK_WAIT | (1,1,0,0) | Waiting for “Start Upload” packet |

| LED_BOOT_UPLINK_COPY | (1,0,1,1) | Waiting for “Continue Upload” pkts |

| LED_BOOT_UPLINK_EXECUTE | (1,0,1,0) | Calling loaded program |

| |

|

Any further usage of the bi-levels is the responsibility of the loaded program.

-

Science Telemetry

-

Once the program has been loaded and started, it is responsible for all science telemetry (if

any).

-

Warning

-

-

1.

- Uses of Load-from-Uplink

Although Load-from-Uplink is a useful diagnostic feature, building loads requires detailed knowledge

of the instrument, DPA hardware, and the ACIS software development environment. Transmission of

load-from-uplink commands does not require much knowledge beyond that described in this document,

but act of building and understanding the effects of programs that use the Load-from-Uplink feature

requires knowledge beyond the scope of this document. It is expected that only the ACIS software

maintenance team will build programs that use this feature. However, it is possible that this team may

request routine uplink loads to perform some types of ACIS maintenance activities.

-

2.

- State of Instrument after a Load-from-Uplink

The state of any on-board stored parameter blocks, tables, etc., is completely up to the loaded

program(s). Some programs may corrupt the state of the instrument, whereas others may leave the

instrument in the previous state.

-

3.

- Watchdog Timer Maintenance

Once a program is loaded from the uplink channel and begins execution, it has up to 3 seconds to reset

the BEP’s watchdog timer. Once running, it is the loaded program’s responsibility to maintain the

timer (NOTE: If the watchdog timer expires, it will reset the BEP. It will not reset the BEP a second

time until the BEP receives either a commanded reset (Halt BEP/Run BEP) or power-on reset).

3.1.4.1 Boot Duration

In the case of a Boot from Uplink (see Section 3.1.4) the boot takes as long as needed for the instructions and data

to be sent to the active BEP in startUpload and continueUpload command packets. Otherwise, it generally

takes 0.3 seconds to copy the contents of EEPROM to D-cache and I-cache, apply patches and begin

executing.

3.2 Halting the software

This section describes how the ACIS instrument software is halted.

3.2.1 BEP Power-Off

This section describes how to power-off the ACIS Digital Processor Assembly (DPA) Back End Processors

(BEP).

-

Description

-

One method of stopping the ACIS software from running is to power-off the “active” BEP. This can

be accomplished by issuing a power-off command or a disable command to the PSMC responsible for

the active BEP (see Section 3.1.2 for a discussion on selecting a BEP). The recommended method is

to first issue the “power-off” command, followed by the “disable” command, however, just issuing the

disable command has the same affect.

-

Commands

-

The following are the commands issued to power-off the BEPs. See Table 2.1 for commands to power-on

the DPA’s BEPs. Also, see Section 3.3.3 for commands needed to enable and power on and off the

Detector Electronics Assembly.

Table 3.7: Power Off Command Sequence

|

|

|

| Mnemonic | Command Type | Description

|

|

|

|

| Power Off Side-A BEP

|

|

|

|

| 1DPPSAOF | Pulse to PSMC Side-A | Power-Off (but don’t disable) the PSMC DPA

Side-A |

|

|

|

| 1DPPSADS | Pulse to PSMC Side-A | Disable the PSMC DPA Side-A |

|

|

|

| Power Off Side-B BEP

|

|

|

|

| 1DPPSBOF | Pulse to PSMC Side-B | Power-Off (but don’t disable) the PSMC DPA

Side-B |

|

|

|

| 1DPPSBDS | Pulse to PSMC Side-B | Disable the PSMC DPA Side-B |

|

|

|

| |

-

Engineering Telemetry

-

For a description of the state of the Engineering telemetry when power is off versus on, refer to

Table 3.2.

-

Science Telemetry

-

When the power is off on a BEP, the science telemetry is undefined, although experience in the lab indicates

that it tends to float to logical ’1’.

-

Warning

-

-

1.

- Lose all loaded parameters and tables

When a BEP is powered off, it loses all loaded parameter blocks, system configuration values, bad pixel

and column maps, patches, Huffman tables and anything else that has been loaded into RAM. When

the BEP is re-powered, the default parameter blocks, tables, etc. will be copied from EEPROM into